Vimal Sonic Infrastructure

The solid infrastructure that Vimalssonic maintains distinguishes us from other businesses in our field. Our facility is strategically located in Dhayari, Pune, India, close off the New Mumbai-Bangalore Express Highway. It is governed by technocrats who are both proactive and visionary, and who possess both extensive experience and functional skill sets. Our dedicated research and development unit is the engine that drives all of our many types of innovation, and it is located at the heart of our business activities. To ensure that we can meet the needs of even the most demanding customers, we have made substantial investments in cutting-edge machinery, flexible control systems, and cutting-edge testing equipment.

Our office space is around two thousand square feet and includes a skilled Design, Assembly, and Commissioning team, as well as a well-equipped conference room and tool room. The floor area of our assembly shop is 8,000 square feet, and it is here that we manufacture custom machines using the necessary assembly equipment. Our research and development centre is 1,300 square feet in size, offering our engineers ample space to concentrate on new product development and innovation.

Because we want things to go as smoothly as possible, we have allocated a 2,000-square-foot parking lot for our customers and employees.

In addition to our state-of-the-art infrastructure, we also have an effective support system that expedites our delivery of products and responses to consumer concerns. Our clientele is fairly diverse, and includes not only prominent Indian firms but also well-known multinational organisations and other international companies that have placed their trust in us. We take great satisfaction in our ability to meet the ever-increasing needs of our clients, while simultaneously aggressively pursuing the objective of continuous improvement.

At Vimalssonic, we are committed to providing cutting-edge solutions while maintaining the highest levels of client approval possible. We are able to achieve a high level of sustainability as a result of our attention to ethical labour practises and responsible material procurement.

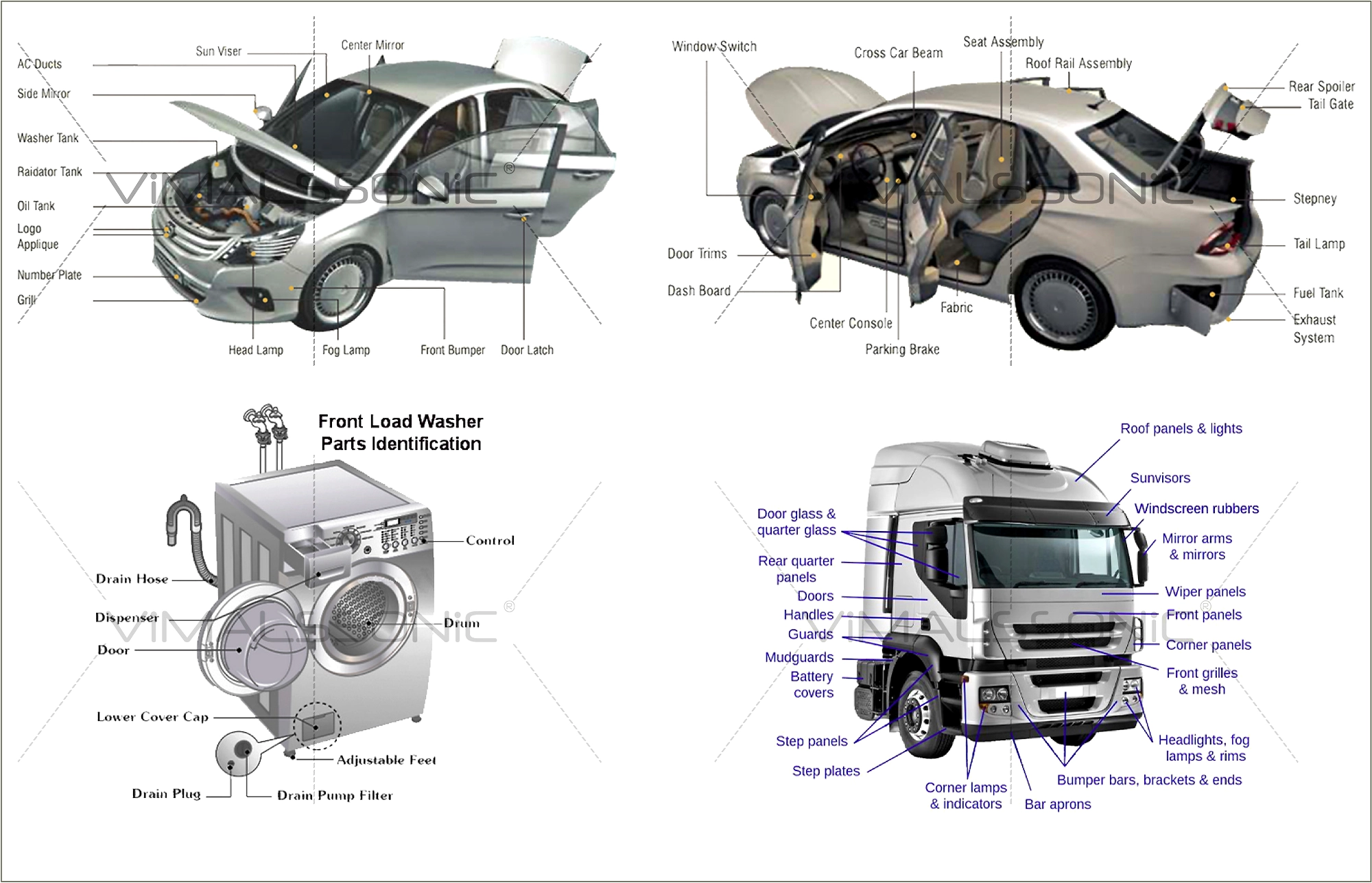

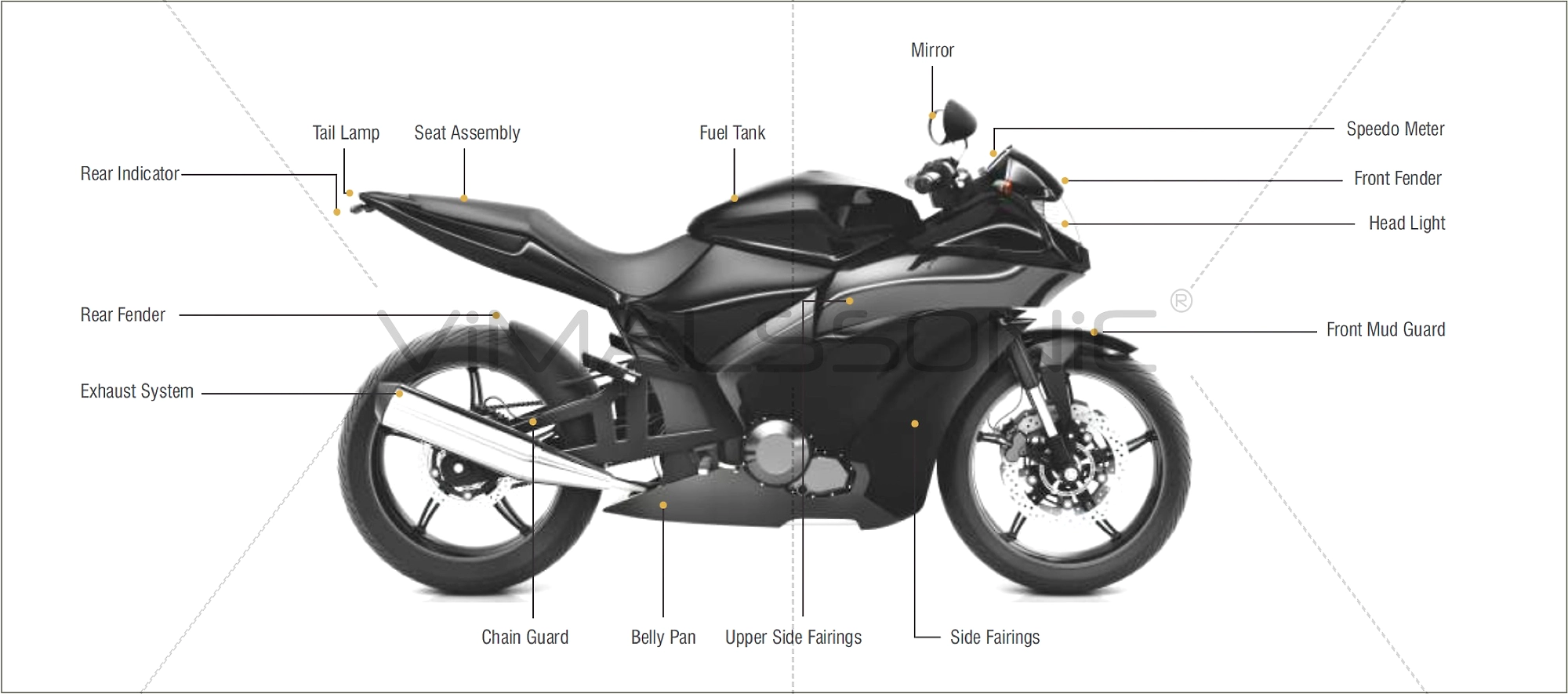

Sector We Serve

Product We Serve

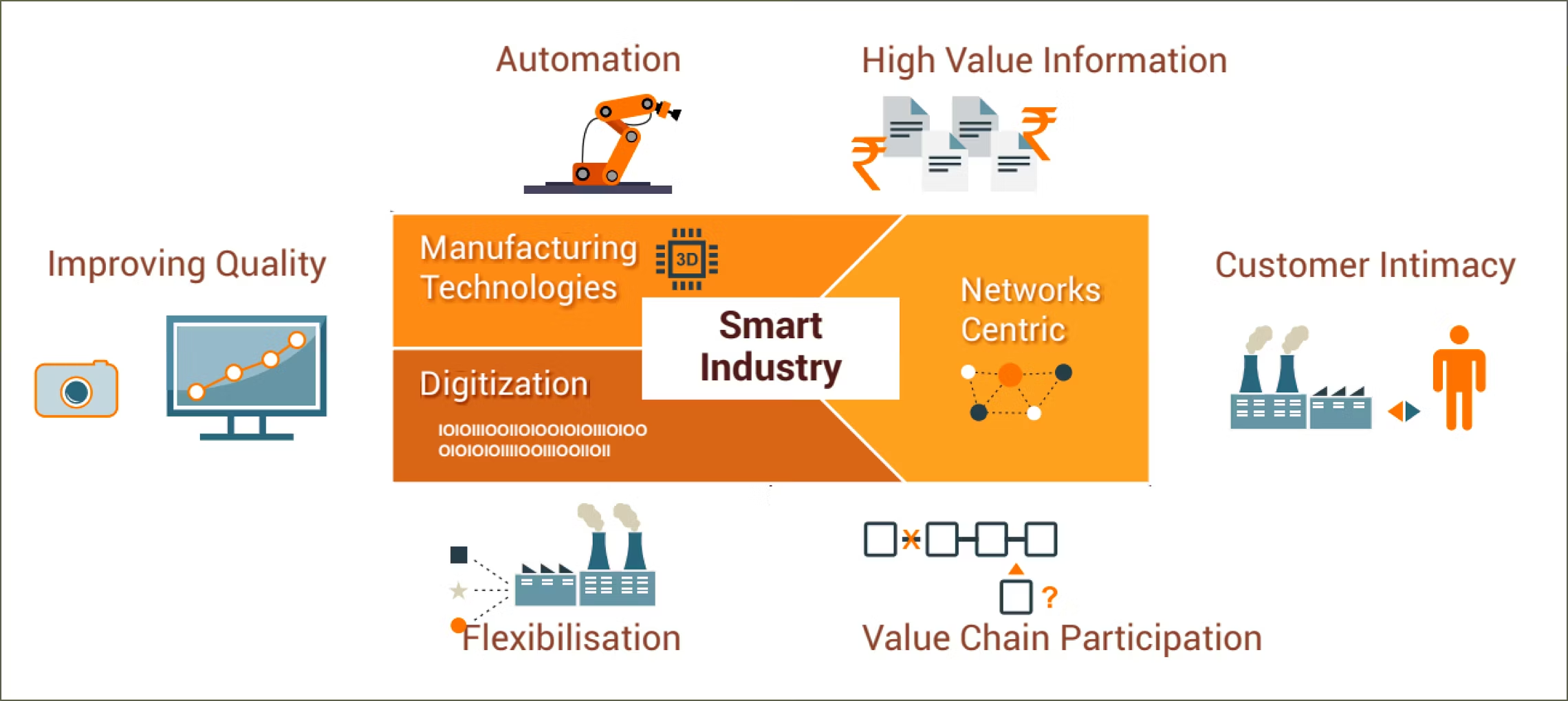

Manufacturing 4.0

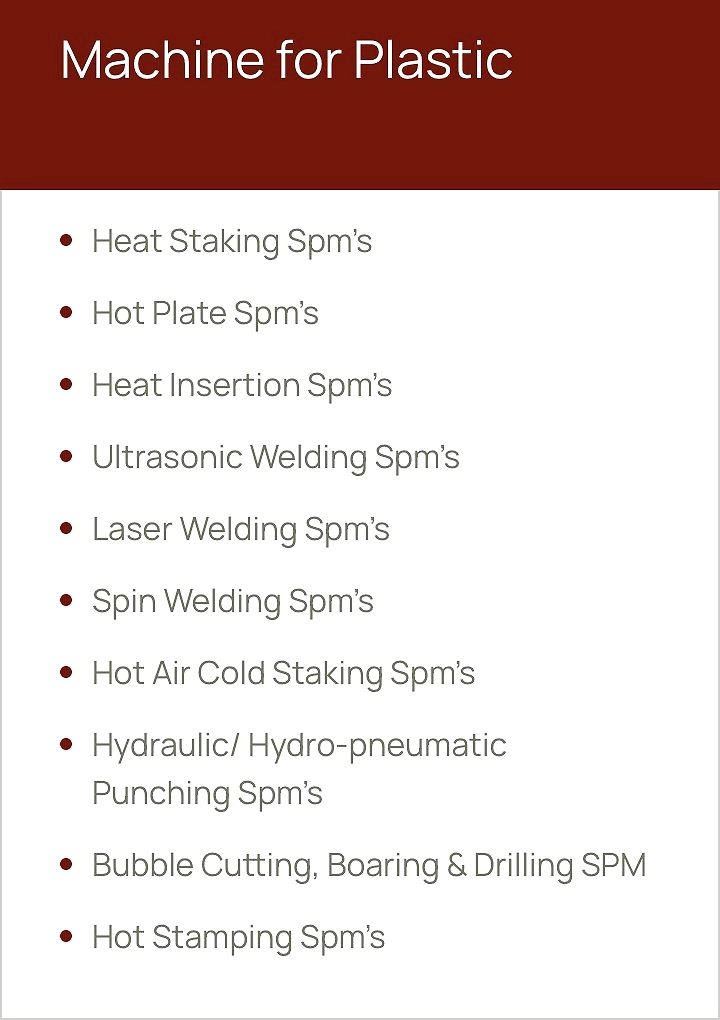

Our Custom solutions for Assembly Automation, Plastic Joining Processes Machines, End of Line Testing Machines

Our Custom Solution for Sub Assemblies & Components of Various Sector